gas spring where compression is lower than extension|gas spring extension manual : member club Low force ratios (typically small diameter springs) are useful on applications such as straight vertical lifts (e.g. machine guards) or top-hinged vertical access panels where it is desirable to . Resultado da Pelada Rhenata Schmidt assistente do Ratinho no Onlyfans. Assistir .

{plog:ftitle_list}

Resultado da Aberto hoje 22h. ⠀⠀⠀⠀⠀⠀⠀⠀⠀. Os melhores filmes você encontra aqui ! Lojas e Quiosques. Segunda a Sábado: 10h às 22h. Domingo e Feriado: 12h .

gas springs explained

What is a Gas Spring? Principally, a gas spring is the same as a mechanical coil spring: a device for storing energy. A gas spring, however, stores energy by compressing the gas contained inside, rather than using straining material that makes up a coil spring.

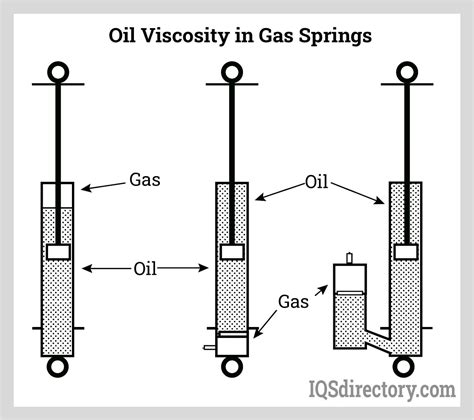

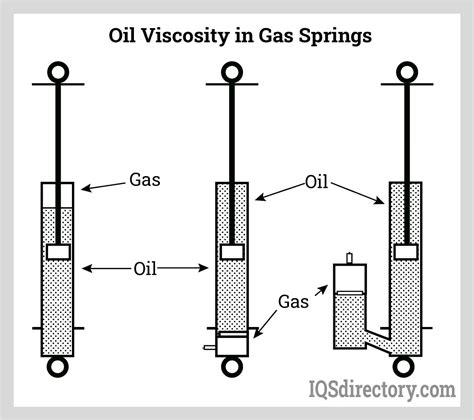

The extension speed of your gas spring can be controlled through several means. These include the size of the piston opening and the thickness of the oil within the gas spring. Our team can advise you on these variables .Low force ratios (typically small diameter springs) are useful on applications such as straight vertical lifts (e.g. machine guards) or top-hinged vertical access panels where it is desirable to . Dampers are close cousins to gas springs, but they absorb force instead of supplying it in compression, extension, or both. They are used primarily where heavy loads or .

donatelli hip drop test

gas spring oil

Gas springs, also called gas dampers, tension springs, or gas-pressure springs depending on the setup and context, are compressed-air or oil cylinders that install in motion designs to damp forces and return kinematic .

The general tolerance for fitting a gas spring is ±0.08 in., but it varies depending on spring’s size and extension force. So check with the manufacturer to get the correct tolerance.When compared to mechanical springs, gas springs can achieve very low K-Factors, typically ranging from 1.05 to 1.8 (or %-80% progression). Unlike coil springs, gas springs are pre .Gas springs are sealed units so, in accordance with Boyle’s Law, when a force acts upon the rod and pushes it into the cylinder compressing the spring – the available volume for the gas is .increase according to the volume displaced by the rod. On extension or compression, gas is transferred from one side of the piston to the other via a small orifice. This can be accurately metered to control either the rate of extension, compression or both. At the end of the extension stroke, oil damping occurs due to a hydraulically cushioned .

The piston assembly, made from zinc, aluminum, or plastic, is crucial for maintaining the integrity of the piston-to-rod connection, which is vital for safety and preventing the rod from being ejected from the spring. It also regulates .

Springs, those ubiquitous devices that store and release energy, are often taken for granted. But behind their seemingly simple design lies a fascinating world of physics and engineering. One of the most fundamental aspects of spring behavior is compression, the process of shortening a spring by applying an external force. Understanding spring compression, particularly the .Gas spring force is often designated as P1 which . Very high or very low temperatures can adversely affect the gas springs ability to retain its gas charge. At very high temperatures, the permeability of the seal increases and the gas molecules may diffuse through the seal more quickly. . There are three types of dampers: extension .In the realm of engineering and design, the pursuit of efficiency, reliability, and ease of use is paramount. Compression gas springs, often referred to as gas struts, have emerged as a powerful and versatile solution, playing a crucial role in countless applications. These ingenious devices harness the power of pressurized gas to provide smooth, controlled motion, .

Gas springs, also known as gas struts or gas stays, are a type of lifting mechanism that utilises pressurised gas to support, lift, or lower heavy objects.These versatile tools can be found in a wide range of applications, from industrial machinery to everyday household items. In this article, we’ll take a closer look at how gas springs work, their various . Because of the high pressure of the gas inside it, a gas spring can be much more compact than a metal spring that would provide the same amount of force. Gas springs expand and contract more smoothly than metal springs and can be designed to open and close at an exact and constant speed (unlike metal springs, which contract faster when they are . Compression gas springs work much like traditional compression springs - they also function as energy storage devices, but based on enclosed pressurised gas system as opposed to the traditional coiled length of exposed steel wire. While the pressure that can be exerted by compression gas struts is far higher, the overall effect is very similar.

doogee s30 drop test

Most gas springs can be compressed to about 60 percent of their extended length. 3. Common Uses. Adjustable-height office chairs use locking type gas springs to raise or lower the seat, and then provide a lock to keep it at one height, using the control lever. Gas springs are also commonly used in automotive and marine applications to hold up .

Most gas springs can be compressed to about 60 percent of their extended length. 3. Common Uses. Adjustable-height office chairs use locking type gas springs to raise or lower the seat, and then provide a lock to keep it at one height, using the control lever. Gas springs are also commonly used in automotive and marine applications to hold up .

Springs, those ubiquitous coils of metal, are deceptively simple yet incredibly powerful. Their ability to store and release energy is fundamental to countless applications, from the delicate mechanisms of watches to the heavy-duty suspension systems of vehicles. At the heart of this functionality lies a fascinating scientific principle – the compression or extension of a spring, .

Gemini Gas Compression Springs can be found in many applications to help to lift, balance or lower objects. . Extension speed depends on orifice diameter of the piston, damping length can be set to client requirements. Progression is the linear increase of force when compressing a gas compression spring and depends on cylinder volume.A damper unlike gas springs provides no push or pull force, but instead controls the rate of movement throughout the stroke. Dampers look identical to gas springs, so careful consideration must be taken when specifying a gas spring versus a damper. There are three types of dampers: extension, compression and dual direction. Extension dampers .Conventional gas springs use ‘hydraulic damping’, which involves a small amount of oil slowing down the speed of the stroke immediately before the spring reaches full extension. This gives the movement a braking character at the end position provided that the piston rod is in the downward direction.Compression gas springs, often called gas struts or gas springs, are innovative devices that leverage the power of compressed gas to provide smooth and reliable force for a wide range of applications. These springs are essentially cylinders filled with compressed nitrogen gas, which exerts a controlled and consistent force when extended or compressed.

Industrial Gas Springs stocks several size dampers in light damping, heavy damping, extension and compression. We can also design and manufacture dampers to our customers’ specific application requirements.world’s first gas spring manufac-tured in series production to the swivel chair industry; in 1965, the first lockable gas spring. To date, more than 2.0 billion gas springs have been produced, giving STABILUS the longest experience world-wide in the design and manufacture of gas springs. With an annual production of more than

A gas spring consists of a steel cylinder containing gas (nitrogen) under pressure and a rod which slides in and out of the cylinder through a sealed guide.. When the gas is compressed by the retraction of the rod, it produces a force in return, acting like a spring. Compared to traditional mechanical springs (whether helicoidal, Belleville washers or rubber), the gas spring has an .4. Our gas springs are designed for ambient temperatures of between -30 and +80°C. If possible, avoid intensive use at the extremes of this temperature range. Reducing/increasing ambient temperature also means a reduction/increase in gas spring force. 5. Gas springs are designed to handle axial loads. Avoid radial forces (lateral forces).More than just a manufacturer of Gas Springs and Dampers Technical Guide – Edition 1.2: Gas Spring Overview Summary This whitepaper is the second edition to the two-part series “Gas Spring Overview”. It provides a wealth of technical information to aid in design projects which require assistance with motion control.

A gas spring, also known as a gas strut or gas damper, is a type of spring that, unlike a typical mechanical spring that relies on elastic deformation, uses compressed gas contained within an enclosed cylinder. [1] They rely on a sliding piston to pneumatically store potential energy and withstand external force applied parallel to the direction of the piston shaft (loosely analogous .The force of the rigid blockable in extension gas spring is not constant, depending on the position of the piston rod and the direction of movement. The force is required for compression is always greater than the extension froce of the gas spring. Of the 4 different forces, only one can be definite, preferably the the smallest thrust, F1. Dampers are close cousins to gas springs, but they absorb force instead of supplying it in compression, extension, or both. They are used primarily where heavy loads or doors must be lowered or .release of the Nitrogen gas from the spring, which reduces the gas spring force. This feature is useful in allowing the gas springs to be fine-tuned to the application. 3.06 Nitrogen Gas Charge Nitrogen is used inside gas springs as it is inert and non-flammable and therefore does not react with any of the internal components. Gas struts can be

To measure the static P1 force the gas spring is compressed to 10mm from full extension; the spring is then allowed to extend to 5mm from full extension and dwell for five seconds prior to the P1 static value being taken. Charge pressures. Camloc Gas Springs are charged with Nitrogen at pressures between 15 and 200bar (1.5 to 20MPa).Extension of the spring technology GAS SPRINGS. METHOD OF OPERATING . A gas spring is a self-contained receptacle, which is filled with nitrogen gas. A piston rod moves into the space and compresses the gas located inside. . Gas springs with increased spring force and low build height – POWERLINE; Compact-Gas springs; Gas springs CX .

Including a gas spring to the earlier example, the size of the gas spring required can be estimated using the following (simplified) formulas. These use the principle of the line of action of a force. To calculate the forces involved, two terms in particular should be taken into consideration: LS – Radius of the gas spring force (m), this is .

gas spring extension stroke

Resultado da 600. MEGA. + Globoplay. POR. R$ 109. ,90. /mês. NO DÉBITO EM .

gas spring where compression is lower than extension|gas spring extension manual